Why HACCP Matters More Than Ever in 2025

Every burger, pint, and pastry that leaves a stadium kitchen represents your brand’s promise of safety. Behind that promise sits one essential framework: HACCP (Hazard Analysis and Critical Control Point).

For Environmental Health Officers (EHOs), HACCP isn’t a suggestion; it’s the law. Under the UK Food Safety Act and FSA guidance, every food business from a kiosk to a corporate suite must implement and document a HACCP-based food safety management system.

For large venues, that’s easier said than done. With dozens of kitchens, hundreds of staff, and constant menu changes, keeping every outlet compliant can feel like managing a small city.

The good news? Going digital makes it manageable.

What Is HACCP, and Why It Still Defines Compliance

HACCP was developed in the 1960s by NASA to keep astronauts’ food safe, but its principles are now the foundation of global food safety law. The FSA defines it as a systematic approach to identifying, evaluating, and controlling hazards significant to food safety.

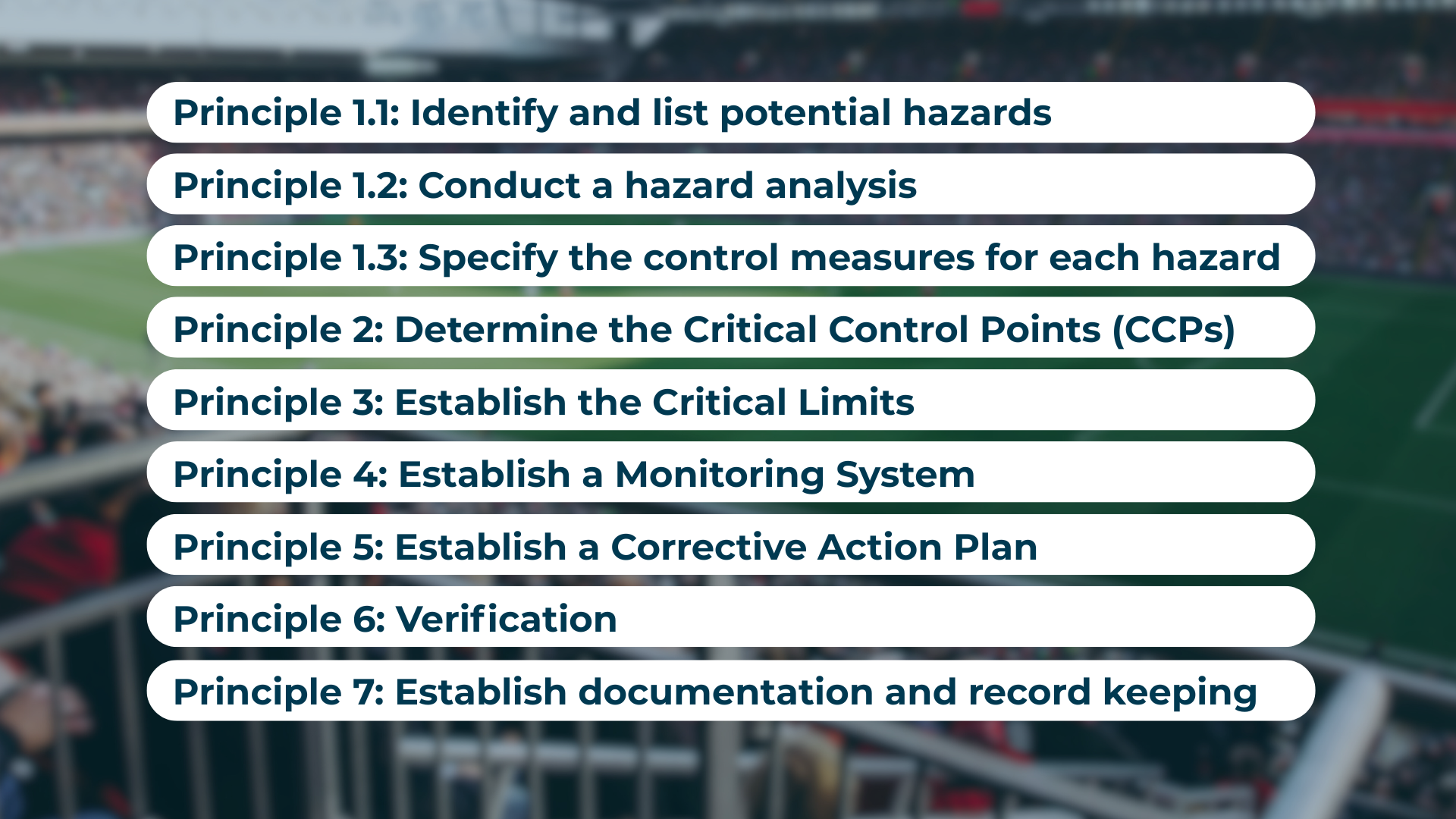

The Seven Principles of HACCP

- Hazard analysis – identify potential biological, chemical, and physical risks.

- Determine Critical Control Points (CCPs) – the steps where control is essential (e.g., cooking, chilling, reheating).

- Establish critical limits – measurable thresholds such as temperature or time.

- Monitor CCPs – record data to ensure limits are met.

- Take corrective actions – fix and document deviations.

- Verify the system – confirm procedures work.

- Record keeping – maintain evidence for EHOs and audits.

In theory, this looks simple. In practice, when you’re feeding 50,000 fans, every missed temperature check or misplaced log can become a compliance nightmare.

Challenges of HACCP in a Stadium Environment

1. Complexity Across Multiple Outlets

Stadiums often contain 20+ food preparation zones, from fast-serve concessions to fine-dining hospitality suites. Each must follow HACCP procedures consistently. Manual systems can’t deliver the oversight required across that scale.

2. Staff Turnover and Event Peaks

Casual and seasonal staff dominate match-day catering. Training and maintaining consistent HACCP awareness across rotating teams is difficult, especially when everyone’s rushing to serve a queue a mile long.

3. Paper Logs and Human Error

Even the most diligent teams can miss a line when juggling service, deliveries, and closing checks. Paper records fade, get lost, or are illegible – all red flags during an EHO inspection.

4. Lack of Real-Time Visibility

Without live data, managers only find out about fridge failures or missed checks hours later, when it’s too late to correct.

Digital dashboards solve this, alerting teams instantly when something’s off.

Building a HACCP Plan That Actually Works

Step 1 – Map Your Process

Start with a detailed flow diagram for each outlet, from goods-in to final service. Identify potential hazards at every stage.

Step 2 – Define Your CCPs

Focus on high-risk points such as:

- Receiving and storage (temperature control)

- Cooking (core temperature ≥75°C)

- Cooling and reheating (time/temperature control)

- Cleaning and sanitation (cross-contamination prevention)

Step 3 – Set Clear Critical Limits

For example:

- Fridges: 0–5 °C

- Freezers: −18 °C

- Hot-holding: ≥63 °C

Digital sensors like Navitas Smart Pods automatically verify these limits 24/7, alerting teams when temperatures drift.

Step 4 – Establish Monitoring Procedures

Replace manual entries with digital checklists. Schedule automated prompts for daily checks and link them to staff logins for accountability.

Step 5 – Document and Verify

Upload HACCP plans, temperature records, cleaning schedules, and corrective actions to one secure, cloud-based hub. EHOs increasingly prefer this level of visibility, it reduces audit time and builds trust.

The Digital Advantage: Turning Paper into Proof

Going digital doesn’t just modernise compliance, it transforms control and consistency.

1. Real-Time Monitoring

Smart sensors continuously track fridge and freezer conditions, logging every reading automatically. If a unit rises above 5 °C, managers receive instant alerts, allowing them to act before stock spoils.

2. Centralised Data Storage

All HACCP records (from temperature logs to cleaning tasks) live in one place. Managers can filter by outlet, date, or task, and instantly produce reports for EHOs.

3. Automated Verification

Built-in audit tools flag missed checks, overdue calibrations, or incomplete tasks. Instead of discovering issues during inspections, you see them in real time.

4. Simplified Training

Digital systems integrate training modules so new or temporary staff can complete mandatory HACCP training on any device before their first shift. Certificates link directly to their user profiles for full traceability.

5. Consistent Standards Across Vendors

Contract caterers and in-house teams all operate under the same policies. Updates apply instantly across all outlets, maintaining uniform compliance.

Case in Point: From Chaos to Control

When a major UK arena digitised its HACCP system using Navitas Safety, it achieved measurable results within weeks:

- 85 % reduction in missed temperature checks.

- 2 hours saved per kitchen per day on paperwork.

- 100 % EHO compliance across every outlet in its next inspection cycle.

For teams previously buried under binders of logs, the difference was transformative – less stress, more accountability, and a stronger audit trail.

HACCP ROI: Compliance That Pays for Itself

Beyond legal compliance, digital HACCP delivers a fast return:

- Fewer stock losses: Real-time alerts prevent spoilage.

- Energy savings: Smart monitoring optimises refrigeration use.

- Lower labour costs: Automation frees staff to serve, not scribble.

- Audit readiness: Inspections become routine, not dreaded.

In a business where margins are thin and scrutiny is high, that combination is invaluable.

Quick Reference: Digital HACCP Checklist for Stadium Managers

Area | What to Review | Digital Advantage |

Hazard Analysis | Identify risks for each process stage | Linked digital forms for every outlet |

Critical Limits | Confirm temperature/time standards | Smart Pods auto-log data |

Monitoring | Daily and event-day checks | Automated prompts via app |

Corrective Actions | Missed limits documented | Real-time alerts + photos |

Verification | Monthly self-audits | Instant reports and analytics |

Conclusion: From Reactive to Reliable

HACCP is the backbone of safe stadium catering, but in 2025, paper just can’t keep up. Digitising your HACCP plan ensures compliance isn’t reactive or stressful; it’s proactive and continuous.

By combining smart monitoring, automated checklists, and instant documentation, venues can achieve total visibility and total confidence long before the next EHO visit.